This is where AET COB Technology stands apart.

The Curious Case of Standard COB

COB technology, at its core, involves directly mounting LED chips onto a substrate and sealing them with a protective coating. While this creates a seamless, durable surface ideal for high-resolution applications, most LED display manufacturers rely on “High Pressure & High Temperature Moulding” processes to apply the protective layer on the led displays.

While this might seem effective at first sight, it’s a stressful environment for the delicate LED chips. These extreme conditions can cause:

- Micro damage to chips which in turn reduces display longevity.

- Colour shift and dead pixels issue due to chip misalignment or heat degradation.

- Increased maintenance over time, impacting total cost of ownership (TCO).

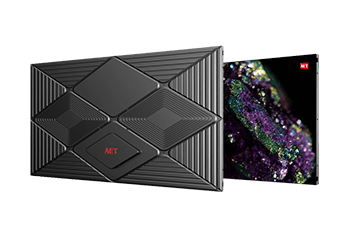

AET’s Innovation: COB Technology That Puts Your Display First

At AET, we’ve reimagined the COB process by eliminating the root causes of chip stress and failure. Our technologies – Advance Patented Gluing (APG) and Special Die Mixing (SDM) — form a rock-solid and efficient COB solution that’s built to last.

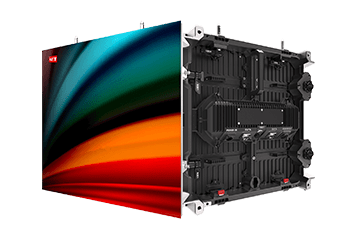

1. Advance Patented Gluing (APG) Technology

Instead of subjecting chips to pressure and heat, APG uses a low-stress bonding technique that gently glues LED dies to the substrate. This preserves the integrity and positioning of each chip, drastically reducing the chance of damage or misalignment.

What it means for you:

- Better chip reliability

- Minimal pixel failure

- Longer screen life

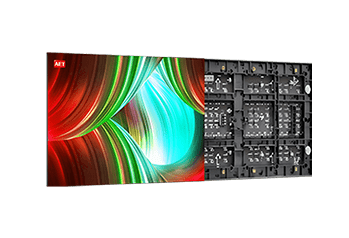

2. Special Die Mixing (SDM) Technology

SDM is AET’s proprietary approach to selecting and placing LED chips with precision, ensuring optimal uniformity in brightness and colour across the display. By intelligently mixing and matching LED dies, we guarantee tight binning control and colour consistency from screen to screen.

What it means for you:

- Flawless visual experience

- No dead pixels or colour patches

- Professional-grade uniformity

But Why This Matters for Your LED Display Projects

Whether you’re building a mission-critical control room, a broadcast studio, or an immersive retail environment, display uptime and visual fidelity are everything. A single flicker or color inconsistency can ruin an experience or send the wrong message.

With AET COB, you get:

- Longer product lifecycle is

- Lower cost of maintenance

- High-grade visuals with no stress-induced flaws

- Confidence in high-performance environments

AET COB vs. Standard COB: A Quick Comparison

| Feature | AET COB (APG + SDM) | Standard COB (High Pressure) |

|---|---|---|

| Coating Process | Low-stress gluing | High pressure + heat moulding |

| Chip Stress & Reliability | Minimal, highly reliable | High, risk of degradation |

| Visual Uniformity | Precise die mixing for uniformity | Inconsistent binning |

| Failure Rate | Significantly lower | Higher over time |

| Maintenance Needs | Reduced | Frequent over long term |

The Future of COB is Here – And It’s Stress-Free with AET

At AET Displays, we believe the future of display technology lies not just in how compact your pixels are, but in how diligently and reliably they are built. With our APG and SDM-backed COB, we are leading the charge toward a more resilient, cost-effective, and visually superior LED world.

So the next time you’re investing in an Led display, just ask:

“What’s beyond the pixels?”

If it’s AET COB — you know you can trust.

0 Comments