AET

MANUFACTURING

Where Innovation Meets Excellence

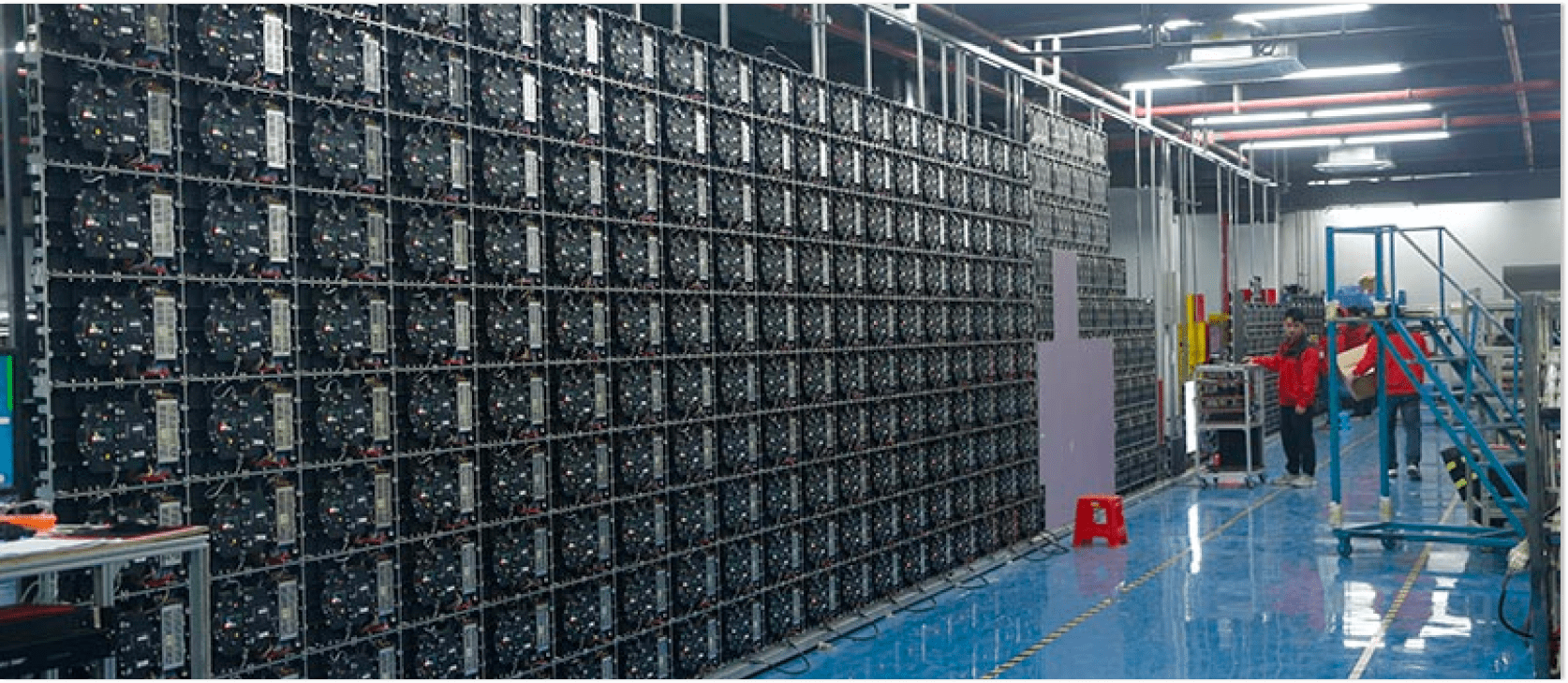

MANUFACTURING UNITS

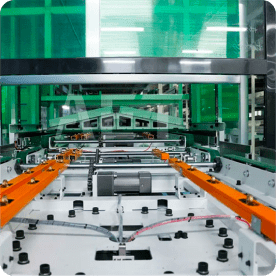

Coretech MicroLED displays limited is a wholly-owned subsidiary of AET Displays Limited (AET). Its established with the concept of “shared smart manufacturing” which allow all customers to make use of the facilities to manufacture the highest quality LED displays. The production facilities have total area of 24000 square meters in one of the Guangda high tech industry park called Liaobu Smart Valley Industrial Park (LSV).

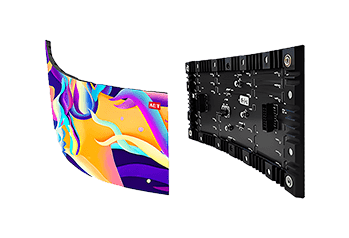

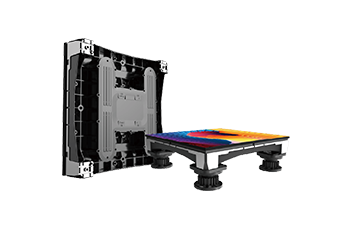

FINE PITCH MANUFACTURING CENTER

Located in Dongguan with a 24,000m production base, Fine Pitch Manufacturing Center is equipped with a high-precision intelligent production workshop, fully automated assembly and aging production line. In addition, production data can be traced in the process.

- 24,000㎡ Production Base

- High-precision intelligent production workshop

- Automatic assembly and aging production lines

- Traceable production data throughout the whole process

- Clear warehouse management for fully automatic manufacturing

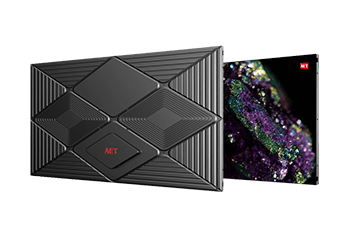

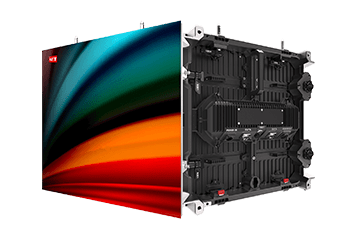

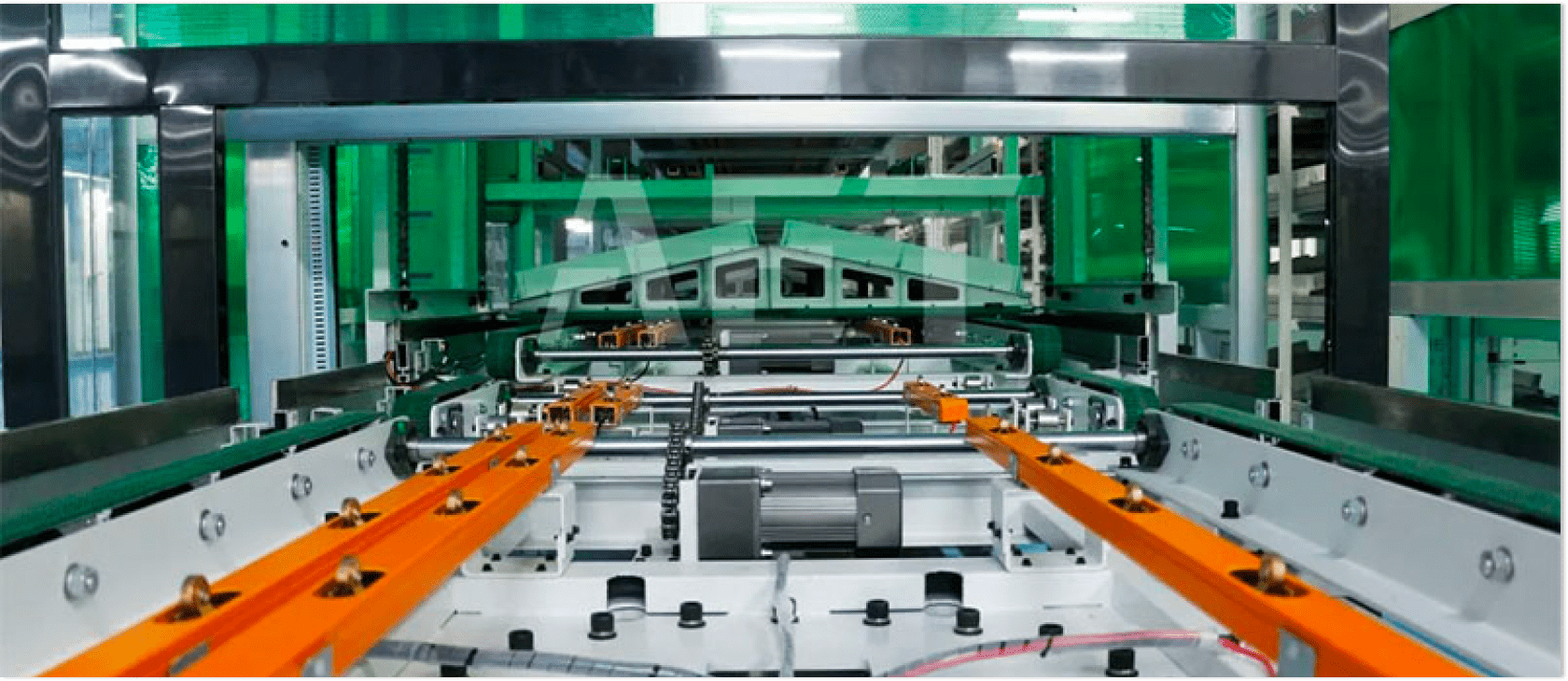

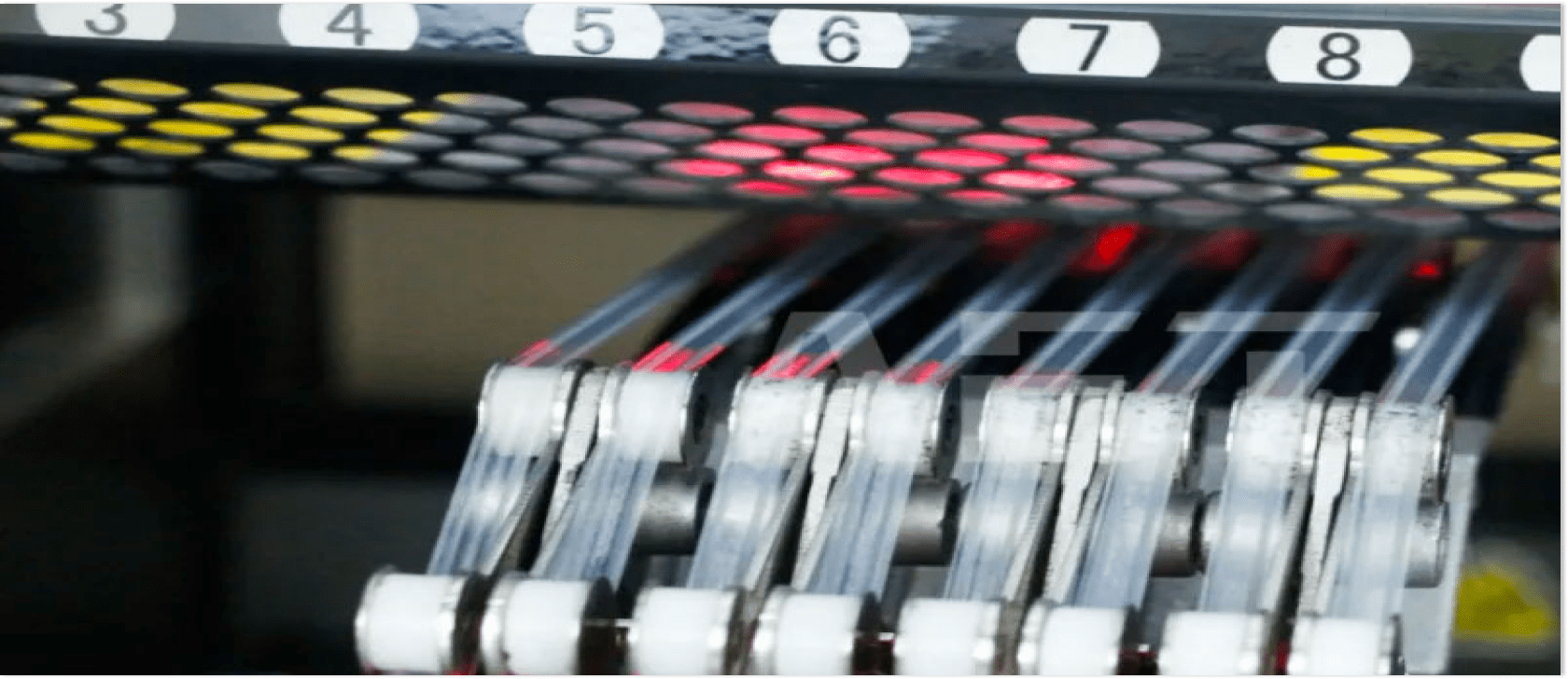

COB MANUFACTURING CENTER

Situated in Dongguan, COB Manufacturing Center serves as a cornerstone in the COB manufacturing, specialising in both OEM and ODM manufacturing base. Boasting a sprawling 100,000+ square metre production floor equipped with numerous automated production lines, it seamlessly supports the mass-production for P0.4-P1.8 COB, achieving a remarkable monthly capacity exceeding 10,000 square metres. This exceptional capability positions it as a leading player in the COB manufacturing landscape.

- AET produces COB LED displays with super-fine pixels, from P0.4mm to P1.8mm. These modules easily snap together to create stunning 4K/8K screens for various application scenarios. AET’s good reputation in the market ensures the top market ranking for our products in China.

- AET pioneered China’s first automated Mini LED production line. AET has already achieved production capacity of 10000㎡ /month with a Mass transfer solution for 50-200 micron chips currently.

- AET’s professional R&D team accounts for 10% of the overall team members, each with over 10 years of R&D experience in the LED display industry.