AET

MANUFACTURING

Where Innovation Meets Excellence

MANUFACTURING UNITS

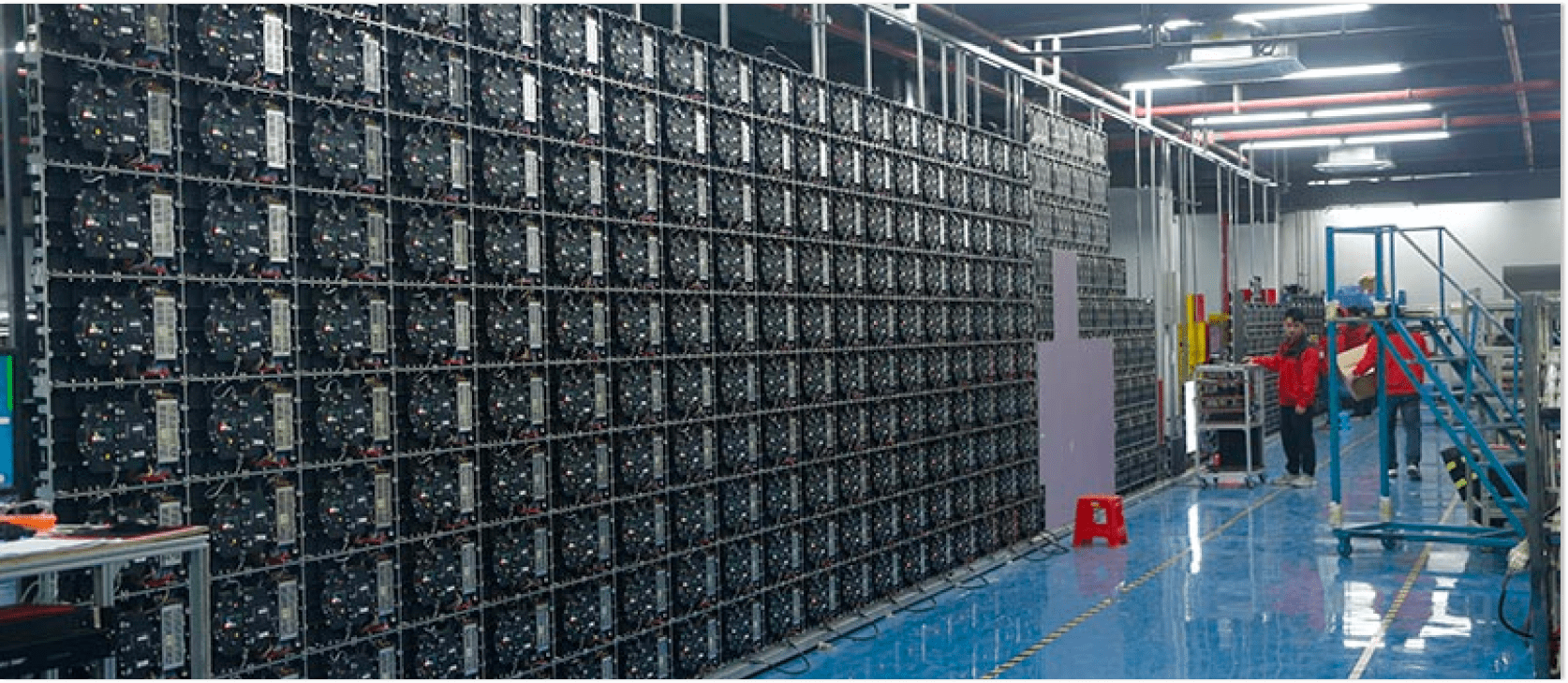

Core tech Micro LED Displays Limited is a wholly-owned subsidiary of AET Displays Limited (AET). Established with the concept of “shared smart manufacturing,” this facility allows all customers to utilize state-of-the-art facilities to produce the highest quality LED displays. Spanning a total area of 24,000 square meters, CoretechMicroLED is located in the prestigious Guangda high-tech industry park, known as Liaobu Smart Valley Industrial Park (LSV). This facility is a testament to AET’s commitment to innovation and excellence in LED display manufacturing.

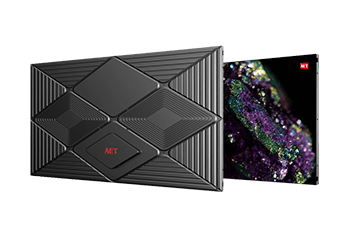

FINE PITCH MANUFACTURING CENTER

Our Fine Pitch Manufacturing Center is strategically located in Dongguan and boasts a 24,000 square meter production base. This center is equipped with a high-precision intelligent production workshop, fully automated assembly lines, and aging production lines. The facilities ensure that production data can be traced throughout the entire manufacturing process, maintaining the highest standards of quality and efficiency.

- 24,000㎡ Production Base: A vast area dedicated to producing high-quality LED displays.

- High-precision Intelligent Production Workshop: Ensures meticulous attention to detail and precision in every product.

- Automatic Assembly and Aging Production Lines: Guarantees consistency and reliability in the manufacturing process.

- Traceable Production Data: Maintains transparency and quality control throughout the entire process.

- Clear Warehouse Management: Supports fully automatic manufacturing, ensuring streamlined operations and inventory management.

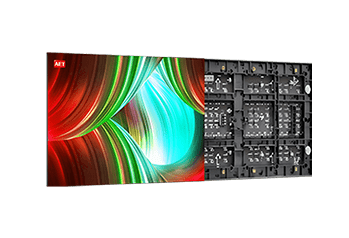

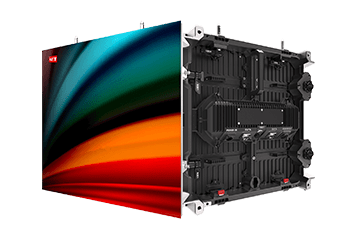

COB MANUFACTURING CENTER

The COB Manufacturing Center, also located in Dongguan, is a cornerstone of COB manufacturing, specializing in both OEM and ODM production. This center features an expansive 100,000+ square meter production floor, equipped with multiple automated production lines, capable of supporting mass production for P0.4-P1.8 COB. With a remarkable monthly production capacity exceeding 10,000 square meters, this center is a leader in the COB manufacturing landscape.

Key Attributes of the COB Manufacturing Center Include:

- Super-fine Pixels: Producing COB LED displays with pixel pitches ranging from P0.4mm to P1.8mm.

- Stunning 4K/8K Screens: Modules that snap together easily to create breathtaking displays for various applications.

- Market Leadership: AET’s reputation ensures our products hold a top market ranking.

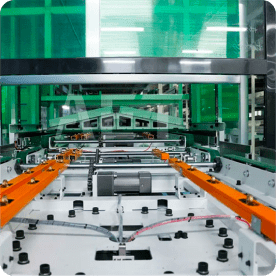

- Innovative Production Line: Pioneering first automated Mini LED production line.

- Mass Production Capability: Achieving a production capacity of 10,000㎡ per month with a mass transfer solution for 50–200 micron chips.

- Professional R&D Team: Comprising 10% of the overall team, each member has over 10 years of experience in LED display R&D.

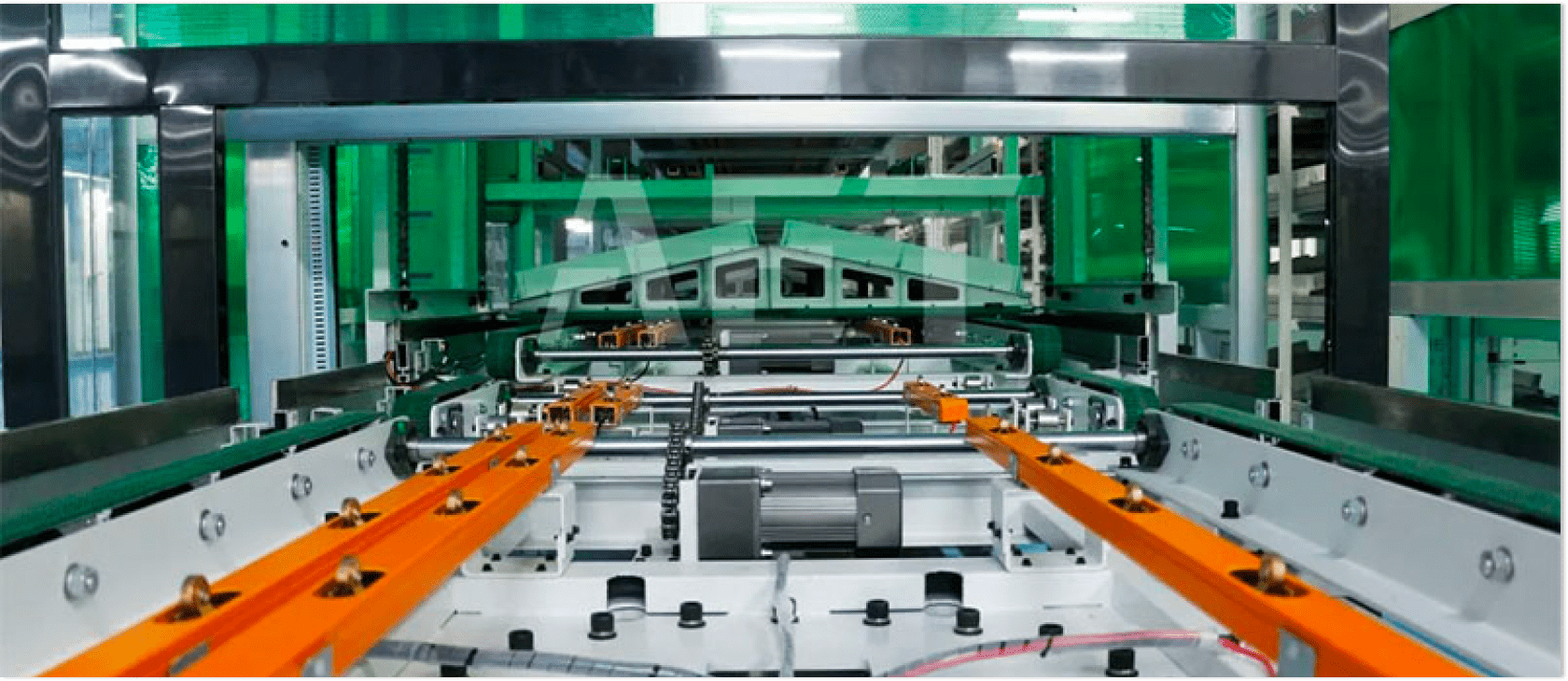

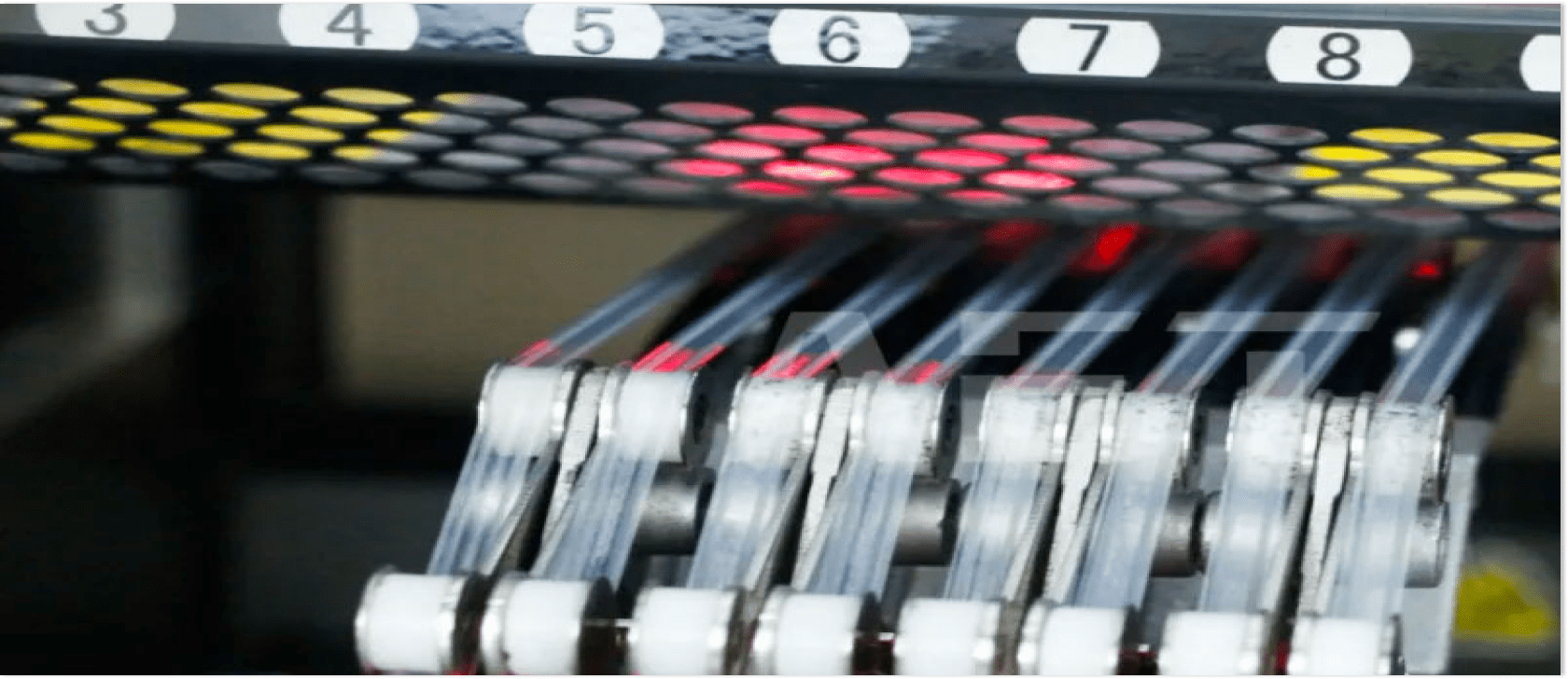

COB MANUFACTURING STATE OF ART EQUIPMENTS

Our COB Manufacturing Center is equipped with the latest in state-of-the-art equipment. We take pride in showcasing different images and videos of our factory, highlighting our advanced technological capabilities and commitment to excellence.

At AET, we believe in pushing the boundaries of what is possible in LED display technology. Our manufacturing units are not just facilities; they are hubs of innovation, quality, and excellence. With our cutting-edge technology, experienced team, and commitment to quality, we are poised to lead the industry and set new standards in LED display manufacturing.

Application SCENARIOS

Malls-Infrastructure

Read More

Broadcast Media Studios

Read More

Retail

Read More

Control Surveillance Centre

Read More

XR Immersive Displays

Read More

Airport

Read More

Railways Metro Stations

Read More

Educational Institutions

Read More

HealthCare Hospitals

Read More

Advertisement

Read More

Corporate Conference Room

Read More