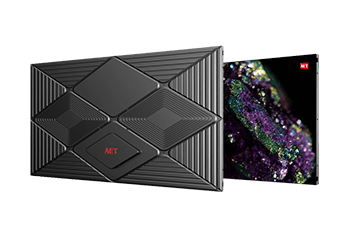

MIP (Micro LED in Package) Technology

With the advancement of LED displays, MIP is a trending technology nowadays. The innovative packaging architecture built on Micro LED involves seamlessly integrating Micro LED with flip-chip devices. In other words, the entire display panel is individually packaged. This approach offers significant advantages in enhancing yield, reducing cost, and improving overall efficiency.

Mass transfer technology is the backbone of this MIP development in terms of integrated LED display modules. AET is the first enterprise to have this MIP technology in the LED display industry. The self-developed Mass transfer production line is now leading the industry with a speed of 2 million chips per hour, and its yield rate is 99.999%

MIP (Micro LED in Package) in the LED display industry is a chip-level packaging technology. Its process is as follows: Micro LED chips are transferred to the carrier board through mass transfer technology, packaged, cut into small packages, and then split and mixed BIN, and taping.

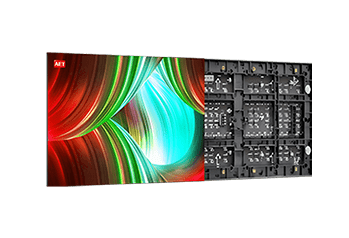

Micro LED in Package (MIP) technology represents a significant leap forward in display technology. Unlike traditional LED displays, which use larger LEDs, MIP technology involves integrating microscopic LEDs into a single package. This miniaturization offers several advantages:

- Versatile pixel pitch- Achieve Ultra Fine Pixel Pitch <= P0.6- Along with High Resolution in Smaller Size

The MIP package is also versatile, that is, an MIP that can be used to produce LED screens with multiple pixel pitches. For example, a 0.4 MIP lamp can manufacture P0.5 to P1.2mm LED displays. In this regard, it is the opposite, both COB and IMD are “package structure determines the final pixel pitch”. MIP is almost the “optimal solution” for mini/micro larger pitch LED direct display screens, suitable for P0.7~P1.8mm Display.

- Prominent Performance

MIP is like a COB package in the form of an independent pixel: it has the reliability of COB chip-level integration and the flexibility of an independent chip, and the reliability requirements for mass transfer in the micro era are 1-2 orders of magnitude lower than COB. The most notable difference between the two is that COB is an integrated package, and MIP is a discrete device package. As a discrete device, the performance advantages of MIP technology are prominent.

- High compatibility

MIP is a typical independent chip bead package and is compatible with downstream SMT processes. In terms of the manufacturing process, MIP technology can match the traditional process of LED display, which means that MIP has higher compatibility in many aspects. For example, LED display manufacturers can use current SMT equipment with a small investment.

- Good Consistency

MIP devices can realize good separation and mixing of wavelength and brightness of chip, which can make perfect color consistency and achieve better visual effects. MIP adopts a flip-chip common cathode structure, which has higher reliability and more energy saving. Because of these a little larger pitches, the application of COB technology on these pitches displays at present is not so cost-effective.

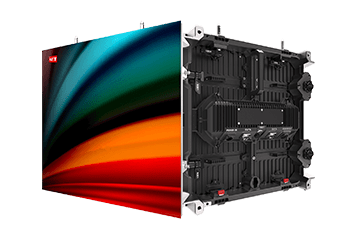

- Improved Brightness&Enhanced Contrast

Micro LEDs are capable of producing higher brightness levels and better contrast compared to conventional LEDs. This results in more vibrant and dynamic images, making displays more visually appealing.

- Energy Efficient

MIP technology is inherently more energy-efficient. The smaller LEDs consume less power while delivering superior performance, making them ideal for applications where power consumption is a critical concern.

- Longevity

Micro LEDs have a longer lifespan compared to traditional LEDs. This durability translates to reduced maintenance costs and longer-lasting displays.

- Facilitate Testing & Post Maintenance

MIP packaging is also easier to test and repair later. Discrete devices offer significant advantages in testing, debugging, conformance selection, and repair.

- Design Flexibility

The compact nature of MIP technology allows for greater flexibility in display design. It enables the creation of thinner, lighter, and more versatile display panels that can be used in various applications.

- Lower Manufacturing Cost

At present, the cost of P1.2mm by MIP technology is equivalent to that of P1.2mm displays produced by COB and SMD, but when the pixel pitch is smaller than P1.2, the comprehensive manufacturing cost of MIP technology is lower than that of COB technology and SMD technology.

- Higher Yield Rate

The essence of MIP (Micro LED in Package) is the combination of Micro LED and discrete devices, that is, the original large-area entire COB display module is divided into smaller separate packages. It is easier to control the yield rate in a smaller area. At the same time, the test process is moved from the chip end to the packaging phase, which will effectively reduce the cost.

- Not Required High Mass Transfer Success Rate

The difficulty of mass transfer yield is not the “mass volume”, but the “yield rate”. The industry once believed that the yield rate of mass transfer needs to reach 99.9999% before it can be applied, that is, in a 4K screen, only about 8 bad transfers can be accepted. Because MIP has to do “discrete device” cutting, final packaging, and testing after the mass transfer of chips, it is not so sensitive to the yield of mass transfer.

- Advantages of Both SMD and COB

MIP packaging technology is essentially a combination of COB technology and SMD technology. It has the characteristics of good color consistency and easy maintenance of SMD and also has the advantages of high reliability of COB.

- Potential Cost Reduction

At present, the most important cost of Micro LED is chip and transfer repair. Among them, the chip cost accounts for nearly 30%. The cost reduction in the future of Micro LED naturally requires smaller-sized chips. From this perspective, MIP is undoubtedly more in line with the future price reduction trend of Micro LED.

- Low Maintenance Requirements

- Harsh Environmental Protection

- Good Heat Dissipation

The Future of MIP Technology

As MIP technology continues to evolve, the potential applications and benefits will expand even further. Here are some trends to watch for in the future:

- Increased Adoption of Display Devices:

As manufacturers recognize the advantages of MIP technology, we can expect to see more consumer devices incorporating Micro LEDs. This will lead to widespread improvements in display quality and energy efficiency.

- Advancements in Manufacturing Processes:

Ongoing research and development will likely result in more efficient and cost-effective manufacturing processes for MIP technology. This will make it more accessible and affordable for a broader range of applications.

- Integration with Other Technologies:

MIP technology will likely be integrated with other emerging technologies, such as augmented reality (AR) and virtual reality (VR). The superior image quality and compact design of Micro LEDs make them ideal for creating immersive AR and VR experiences.

- Environmental Impact:

The energy efficiency and longevity of MIP technology contribute to a reduced environmental footprint. As sustainability becomes a more pressing concern, the adoption of MIP technology could play a significant role in reducing the energy consumption of display devices.

0 Comments